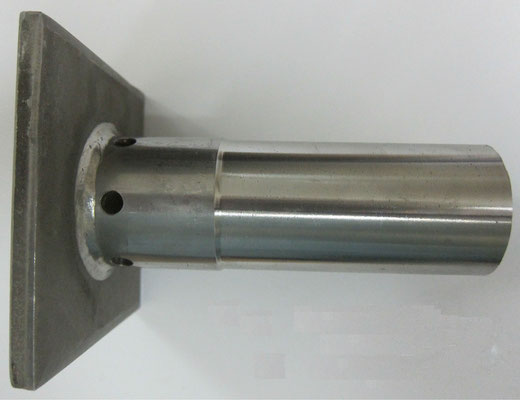

Stamped/Fabricated Sheet Metal Components

STAMPING & FABRICATION

At Metal Forms Private Limited (MFPL), stamping and fabrication are at the heart of our manufacturing excellence. With over six decades of experience, we combine advanced machinery, proven processes, and skilled engineers to deliver precision‑engineered components for diverse industries.

With four integrated manufacturing units around Chennai, we combine state‑of‑the‑art equipment, lean manufacturing practices, and certified quality systems to serve global OEMs in Automotive, Railways, Wind Energy, Earth‑Moving, and Industrial sectors.

MFPL supplies MS and SS stamped and fabricated assemblies for a wide range of industries, including:

-

Automotive: cross members, brackets, chassis reinforcements.

-

Railways & Metro: housings, support panels, and structural members.

-

Energy – Wind & Solar: nacelle components, windmill brake housings, solar tracker structures.

-

Industrial Equipment: enclosures, brackets, heavy‑duty linkages.

-

Earth Moving & Off‑Highway: loader brackets, reinforced arms, and wear‑resistant fabricated parts.

Inspection & Quality

At MFPL, quality is not an afterthought — it is built into every stage of our stamping and fabrication process.

From raw material selection to final inspection, we follow rigorous systems that ensure every part meets the highest standards of dimensional accuracy, structural integrity, and finish. Supported by:

-

FARO Arm CMM, inline gauges, and weld quality validation

-

Certified to ISO 9001, ISO 14001, ISO 45001, IATF 16949, EN 15085‑2 CL1

Infrastructure

-

CNC Turret Punching

-

Handles sheet sizes up to 1.5 m × 3 m

-

Punching thickness up to 6 mm (MS), 4 mm (SS)

-

Ideal for small batches to high‑volume runs with quick tool changeovers

-

-

CNC Laser Cutting

-

Fiber laser cutting with excellent edge quality and repeatability

-

Cuts up to 18 mm mild steel, 8 mm stainless steel, and 6 mm aluminum

-

Perfect for intricate shapes, prototypes, and short lead time requirements

-

- Mechanical & Hydraulic Presses

-

-

Press tonnage from 25 tons to 1,100 tons

-

Suitable for deep drawing, bending, and stamping of high‑strength steels

-

-

- Press Brakes & Forming

-

-

High‑accuracy press brakes up to 4 m bed length

-

Bending thickness up to 12 mm mild steel

-

Roll forming capabilities for structural sections

-

- Welding Facilities

-

-

Robotic MIG Welding Cells:

– High‑speed, repeatable welds for large batches

– Cell size accommodates components up to 2 m × 2 m

-

Manual Welding:

– MIG, MAG, TIG, and Spot welding stations

– Experienced welders certified to EN 15085‑2 CL1 for railway applications

– Heavy fabrication bays for assemblies up to 12 m in length

-